Contact Us

Contact Us

Mining

DynaIndustrial has the resources and industry expertise to design and service equipment in all sectors of the mining industry including potash, coal, uranium and trona. We are customer focused and take pride in providing custom solutions and delivering quality products to our mining clients. Our commitment to quality is demonstrated in our ISO 9001:2015 registered status.

Our clients in both soft-rock and hard-rock mining rely on us for custom design, repair and remanufacture of underground or surface mining equipment, replacement parts, conveyor components, handling equipment, processing equipment and structural steel.

Our work with the coal mines includes repair and maintenance of swing gear cases, hoist gear cases, walking shafts, cam assemblies, dragline pinions, drag shafts and drum assemblies.

Our work with the uranium mines includes hydraulic cylinder repair and project work such as bridge cranes and monorail systems.

Regardless of the mine, safety is of the utmost importance both for our employees and for our clients and we are committed to keeping each other safe. Our commitment to safety is demonstrated in our ISNetworld compliance, internal policies and procedures and innovative solutions.

Project Samples

The DynaBolter is a semi-automated, single operator, roof-bolter that incorporates impressive features into its innovative design. Whether your mine is looking for a machine that improves safety, increases efficiency, or provides optimal versatility, the DynaBolter is the machine that has your back covered. The DynaBolter Advantages:

- Unsurpassed Safety: Operators are able to install bolts from the safety of the cabin.

- Multiple-Bolt Carousel: The multiple-bolt carousel improves efficiency by decreasing the time required to reload after each bolt is installed.

- Intuitive Controls: Dual joystick controls & onboard LCD operation screen make training DynaBolter operators easy.

- Automated Epoxy Injection: The automated epoxy injection system takes the guess work away the DynaBolter operator.

- Low Profile: The DynaBolter’s low profile design allows the operator to navigate through restrictive mines with low backs & tight drifts.

- Dynamic Boom: With up to 3 axis of movement it is easy to manipulate the DynaBolter head into position.

- Customization: DynaIndustrial is not afraid to customize a bolting solution to meet the client’s needs. From chassis choice, to bolt length, to bolt style, to epoxy injection to electric power pak options, with in-house engineering and state of the art manufacturing facilities, the possibilities are endless.

- Service and Support: You can rely on our team of highly trained engineers, millwrights, and CWB certified welders to serve you. With on-site training, commissioning and preventative maintenance schedules your operators will be installing bolts in no-time.

- Parts Support: The DynaBolter is manufactured with high quality parts. With an inventory of spareparts and a quick turnaround for non-stocked items, your downtime will be minimal.

Founded over 145 years ago, Broadbent is a well established and highly respected design and manufacturing company based out of the United Kingdom. The company has an impressive portfolio of products, one of which is their industrial centrifuges.

The Broadbent Centrifuge

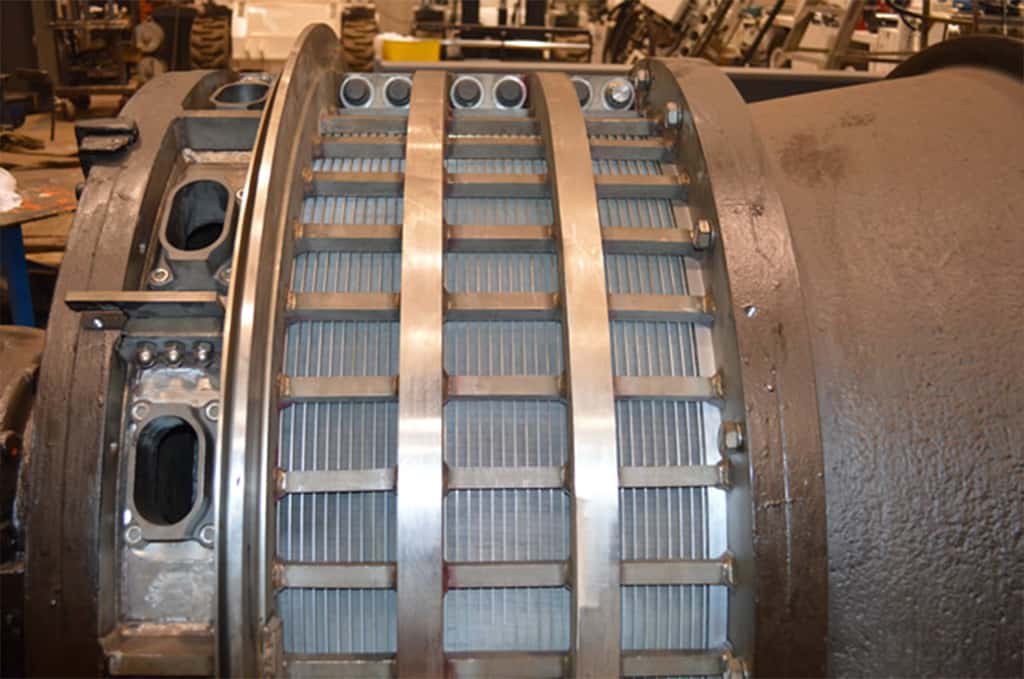

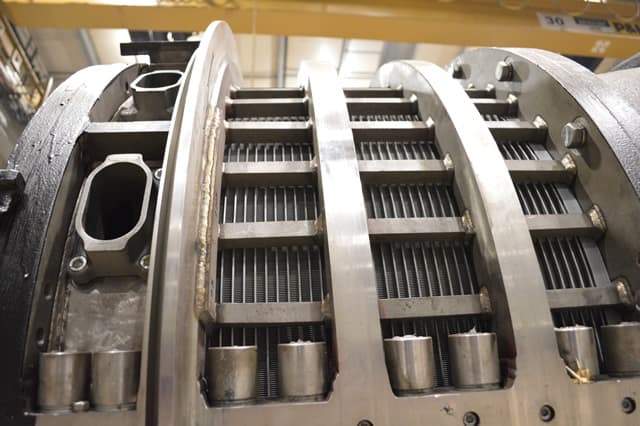

The Broadbent Centrifuge boasts impressive features and improvements that set it apart from traditional models. Improvements to the centrifuge include new screen technology, improved abrasion protection materials and a higher capacity gearbox. Each feature, whether working together or individually, improves process performance, capacity, and helps to extend the life of the equipment between major overhauls. Another bonus about working with Broadbent is that these features aren’t only included on new designs, but can be retrofitted onto older (Broadbent or competitor) centrifuges to improve process performance and reliability.

In order to meet the needs of clients in Canada, Broadbent and DynaIndustrial have formed a partnership. DynaIndustrial is able to provide the quality and capacity that Broadbent requires to properly support each client’s repairs, service or conversions.

With over 100 years of centrifuge manufacturing experience, and 30 years of supplying centrifuges to the potash industry, Broadbent along with DynaIndustrial has the expertise to provide the quality of product each mine needs.

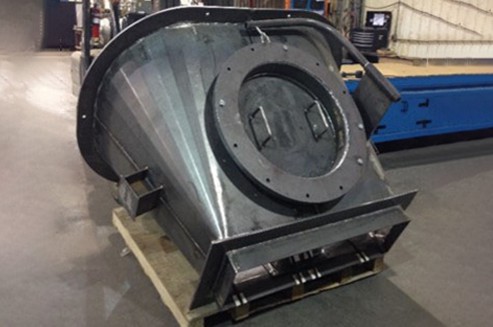

Go for the Gold! Call DynaIndustrial to fabricate all your chutes and skirt boards. Full QA turnover package and complete shop assembly and testing means less downtime at commissioning.

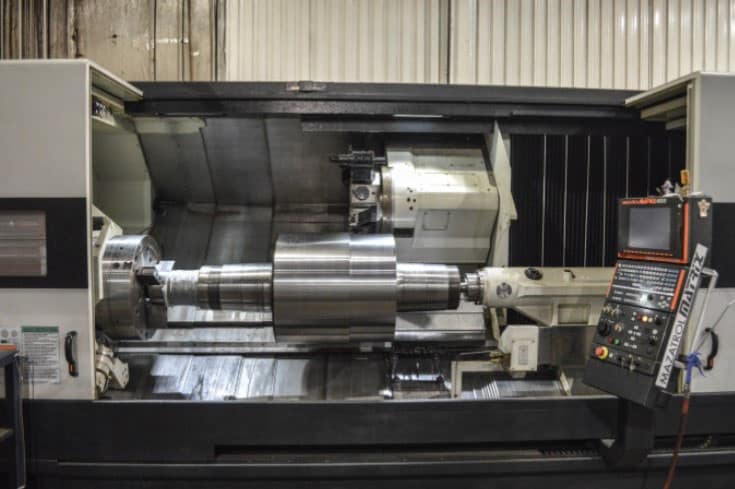

Our large capacity Mazak lathe is the perfect machine to rebuild compactor rolls. The live tooling function of the Mazak lathe enables us to utilize a single machine for the entire rebuild. As well, all hard-chroming is done in-house so DynaIndustrial controls every step of the production process. This ensures that our clients receive the highest quality product.

Customization:

Whether the client requires a different type of bearing, profile, or roll diameter size, DynaIndustrial has the ability to meet each client’s unique needs.

State of the Art Manufacturing:

Our large capacity lathe allows for a complete compactor roll rebuild. Utilizing only one machine guarantees a high quality product.

Quality Controlled:

All services; machining, welding, complete disassembly/assembly and documented testing are performed in-house. This allows us to maintain quality control over the entire production process.

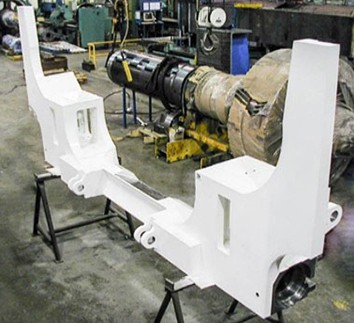

DynaIndustrial has extensive experience with the manufacture, rebuild and refurbishment of all rotary miner components.

DynaIndustrial is able to rebuild and redesign any replacement parts for a potash miner including; top bars, bottom bars, corner extensions, rotor arms, tail conveyors, track frames, trim chain idler rolls, pusher plates, canopies and trim chain shear plates. DynaIndustrial’s team of engineers can reverse engineer and create drawings for any piece of equipment.

Not only do we have the capabilities to manufacture from print but we can also design projects that range in size from small to large, simple to complex, and a single unit to multiple units. So whether it is surface or underground, capital equipment or repairing OEM, DynaIndustrial is your single source provider.

With 24’ under the hook, 20 ton crane capacity, a quality assurance program which includes a full document turnover package and CWB certified in-house level 2 inspections, fabrication of this 35’ conveyor was no problem for the DynaIndustrial team.

Project: Compact Conveyor Belt Cleaner

What it does: Cleans up material that spills off conveyor belts and collects on the floor of the mine.

What DynaIndustrial did: DynaIndustrial designed and built a novel piece of equipment to attach to the customers small walk behind skid steer units. This attachment conveys material from underneath the customer’s conveyor belt systems and moves the material up a vertical chute to deposit it back onto the material conveyor.

Value added: Previously, cleaning under the conveyor belts was a strictly manual process, which was very labor intensive. Additionally, when the material is agitated it becomes airborne and is very irritating to the skin and respiratory system of mine workers. Our compact conveyor belt cleaner attaches to the customer’s existing skid steer and is powered by the auxiliary hydraulic system of the machine, which eliminates the manual effort of the worker. The method of conveyance used by the cleaner keeps airborne dust to a minimum, which helps to create a safer work environment in the mine.

How can we help?

With decades of experience, an in-house team of engineers and state of the art manufacturing, DynaIndustrial will design and manufacture a solution to solve your most challenging problems.

Contact us today by emailing sales@dynaindustrial.com or calling

306.359.7088 (Regina, SK) or 306.933.4303 (Saskatoon, SK) .